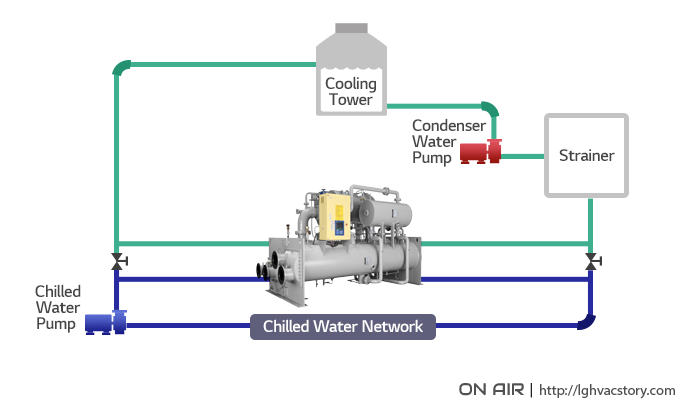

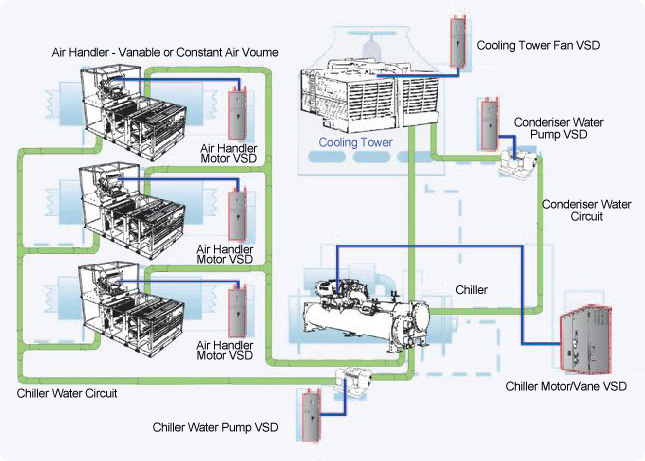

In air conditioning systems chilled water is typically distributed to heat exchangers or coils in air handlers or other types of terminal devices which cool the air in their respective space s.

Chiller vs air conditioner efficiency.

Increasing population level of comfort and high penetration of it technologies are putting strong pressure on electric grids and driving up overall energy.

The dry bulb and wet bulb temperatures can be measured at the ahu inlet and outlet.

The central chiller plant supplies chilled water and conveys it to the user buildings via underground chilled water pipe network.

Comparatively ac are less costly when compared to chiller maintenance but maintenance experts of chiller companies in sharjah.

Better chillers from the inside out.

These cooling coils transfer sensible heat and latent heat from the air to the chilled water thus cooling and usually dehumidifying the.

Air cooled chillers are used commercially and in industrial facilities to cool fluids and dehumidify air in larger venues such as factory floors arenas and larger facilities like hotels.

These systems work great in bigger homes due to their high cooling capacity.

The differences between air conditioning and chillers can be subtle at the cooling process level but very different in applied usage.

The performance of this standard unit is based on ashrae standard 90 1.

The supply ducts circulate the cold air to the entire building.

The water is then recirculated to the chiller to be recooled.

Types of air conditioner vs chiller types of air conditioners central air conditioners.

Today the central air conditioners stand as one of the most commonly used cooling systems in the world.

Dcs is an energy efficient air conditioning system as it consumes 35 and 20 less electricity as compared with traditional air cooled air conditioning systems and individual wacs using fresh water cooling towers.

Default values the values pre loaded into the calculator represent average operating conditions in the federal sector.

However using state of the art technology with centrifugal compressors and variable speed control air cooled chillers are often the better.

Conventional thinking has been that water cooled chillers are more efficient than air cooled chillers.

The constant innovation in chiller design is driven by new demands for energy efficiency local regulations and standards such as leed combined with requirements for new low gwp refrigerants.

C energy efficiency ratio eer 12 kw ton rating 9 5 4 performance evaluation of air conditioning systems for centralized air conditioning systems the air flow at the air handling unit ahu can be mea sured with an anemometer.

Maintenance is very important for both air conditioners and chillers.

If we only look at compressor costs this may be true.

Base model values represent a 100 ton air cooled electric chiller operated for 2 000 full load hours per year with an eer of 9.

Various applications are possible including air conditioning applications industry type process cooling and large scale district heat source systems.