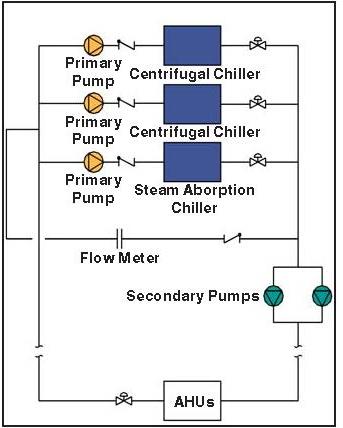

System flow below chiller min flow 250 gpm variable primary flow at 25 system load two way valves control capacity by varying flow of water in coils per chiller system load 50 tons 176kw 50tons 176 kw primary bypass flow 250 gpm 95 l s 150 gpm 9 5 l s delta t 12 of 6 7 oc 100 gpm 44 ºf 6 3 l s 6 7 ºc 56 ºf 13 3 ºc 150.

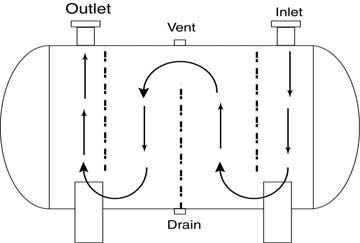

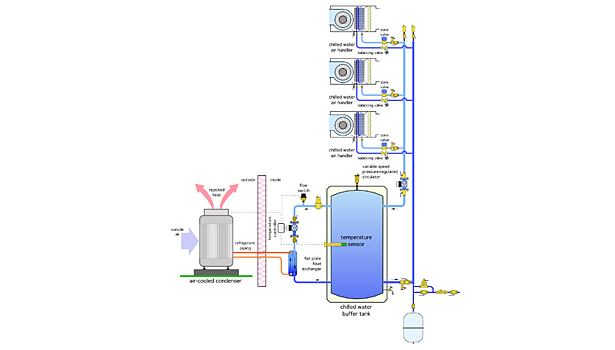

Chilled water buffer tank piping schematic.

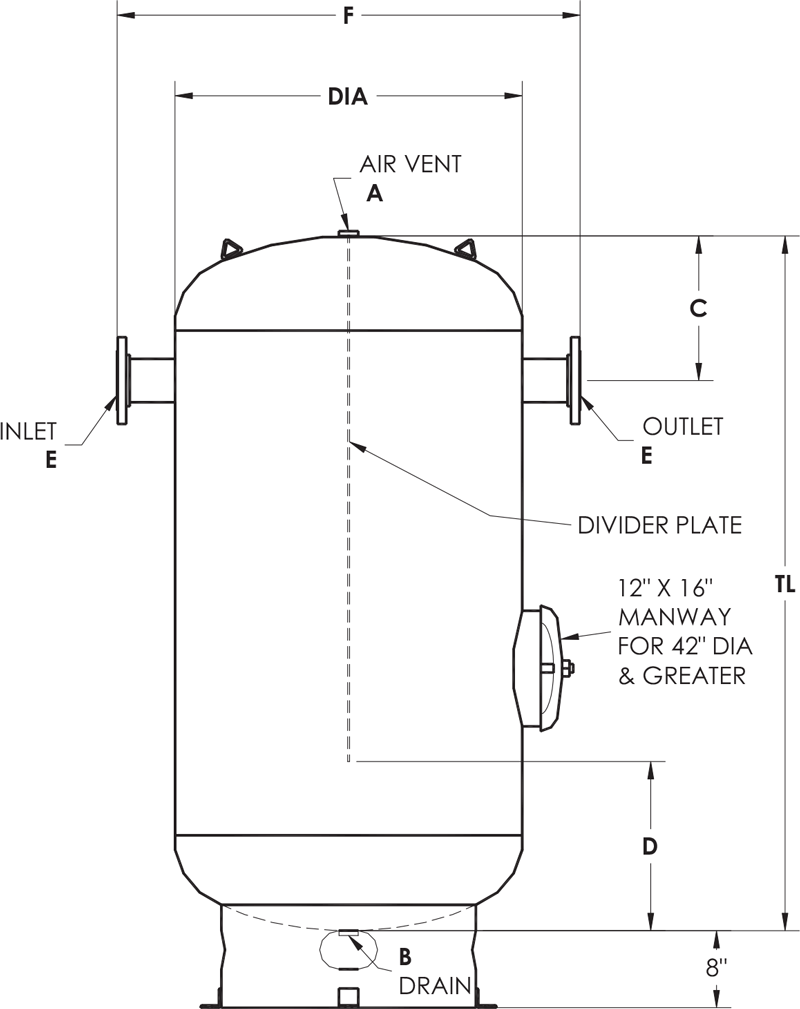

Subtract that number from the chiller manufacturers recommended system capacity.

To properly size the buffer tank calculate the systems total capacity including all piping and terminal equipment.

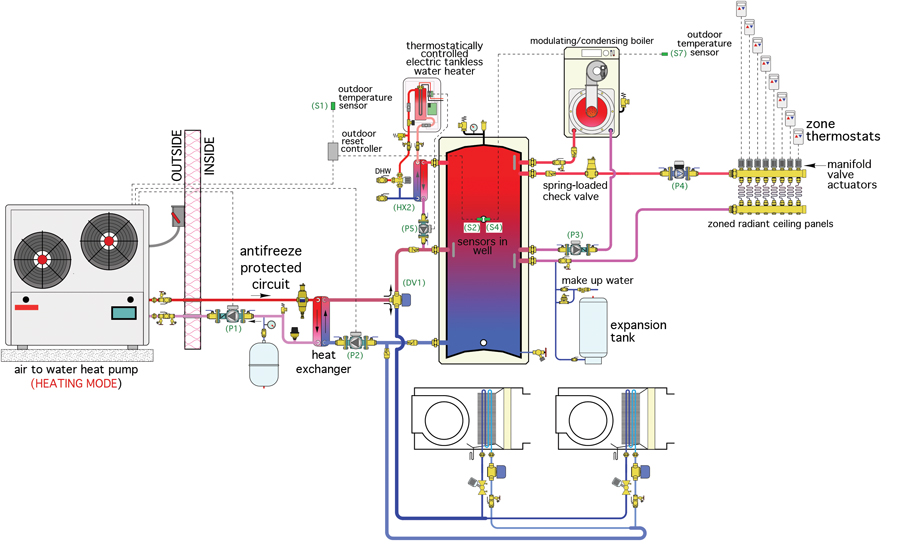

Thermal storage tanks tes blow down condensate cooler cbo boiler blow down tanks bot after coolers ac tank after coolers tac flash tanks fst non electric condensate pumps ccp heat recovery hrs electric boilers.

The insufficiently sized systems do not have enough buffer capacity for the chilled water causing poor temperature control erratic system operation and excessive compressor cycling.

In this article we l be covering chilled and condenser water schematics to learn how to read them how to identify the main components and symbols as well as real world examples additionally we ll cover the purpose of the main components and different design types.

Chilled water buffer tanks cbt and hot water buffer tanks hbt.

Cemline chilled water buffer tanks cwb are designed to be used with chillers which do not have water volumes of sufficient size in relation to the chiller.

Cbt asme chilled water buffer tanks cbt are designed for chilled water systems with insufficient water volume capacity in relation to the chiller capacity.

W essels company manufactures two styles of buffer tanks.